RAIL TRACK EQUIPMENT FABRICATION

- Home

- RAIL TRACK EQUIPMENT FABRICATION

Localized Railway Track Equipment

UpFirst Corp. specializes in the design, fabrication, and supply of localized railway track equipment engineered to meet the rigorous demands of rail maintenance and operations.

Our portfolio includes a wide range of manual and mechanical tools, lifting jacks, rail changers, rollers, cutters, and trolleys—all developed to improve efficiency, safety, and reliability in railway construction and maintenance.

Each product is built with high-strength materials, precision workmanship, and safety-compliant design features, ensuring long service life even under heavy-duty field conditions. We also provide custom fabrication per client specification, along with free design consultation to achieve optimal performance and cost efficiency.

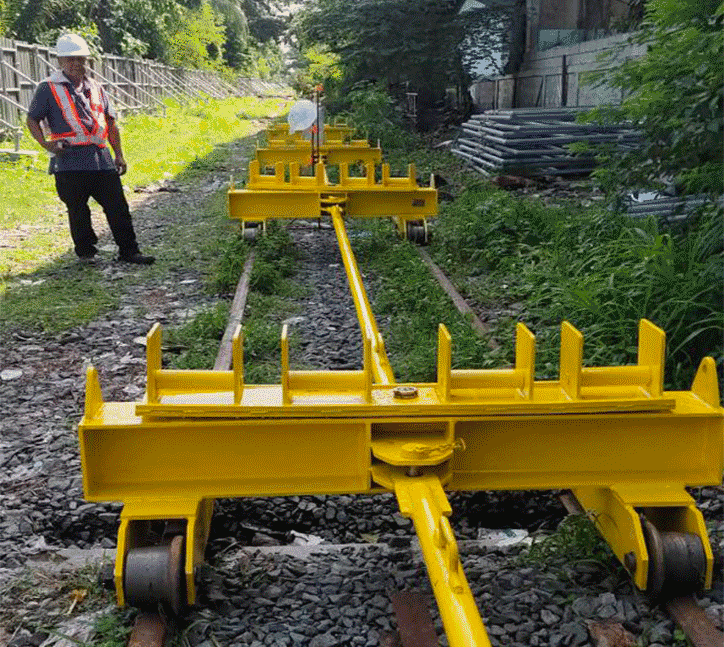

1. RAIL TRANSPORT TROLLEY

KEY FEATURES AND BENEFITS:

- TOWED UNIT SPECIALLY DESIGNED TO TRANSPORT RAILS, SLEEPERS, PANELS, ETC. IN NARROW-GAUGE RAILS.

- IT CAN BE CONFIGURED TO MORE THAN 2(TWO) TROLLEYS DEPENDING ON THE JOB REQUIREMENTS.

- MADE FROM HEAVY-DUTY STEEL FRAME WITH 4(FOUR) HEAVY-DUTY STEEL WHEELS.

- IT FEATURES A PIVOTING PLATFORM TO SAFELY NAVIGATE TIGHT CURVES.

- CAPACITY: 3 TONS WEIGHT: 320 +/-KGS

- OVERALL DIMENSIONS: 1470MM X 690MM X 640MM WHEEL DIAMETER: 200MM

- NO. OF RECOMMENDED OPERATORS 2 (1 SKILLED AND 1 HELPER)

SAFETY FEATURES:

- STRUCTURAL INTEGRITY ROBUST MATERIALS: HIGH-STRENGTH.

- MATERIALS FOR THE FRAME AND BODY TO WITHSTAND IMPACTS AND HEAVY LOADS.

- REINFORCEMENTS: REINFORCEMENTS IN CRITICAL AREAS TO IMPROVE STRENGTH AND DURABILITY

- STABILITY ENHANCEMENTS LOW CENTER OF GRAVITY.

- DESIGN TROLLEYS WITH A LOW CENTER OF GRAVITY TO REDUCE THE RISK OF TIPPING.

- STABILIZING FEATURES: UTILIZE ANTI-DERAILMENT DEVICES AND WIDER WHEELBASES FOR ENHANCED STABILITY.

- REFLECTIVE MARKINGS: HIGH-VISIBILITY PAINT AND MARKINGS ENHANCE VISIBILITY, ESPECIALLY AT NIGHT OR IN LOW LIGHT.

- WEIGHT DISTRIBUTION CONTROLS: THE DESIGN ALLOWS FOR EVEN WEIGHT DISTRIBUTION TO MINIMIZE TIPPINGFABRICATION LEAD-TIME: 8-10 WEEKS

– FABRICATION LEAD-TIME: 8-10 WEEKS

– CUSTOMIZED PER CLIENT’S SPECIFICATION

2. RAIL CHANGER FOR NARROW GAUGE

RAIL CHANGER FOR NARROW GAUGE

Key Features and Benefits:

- LOAD HANGING CAPACITY, 1.5 TONS

- SET WITH GANTRY CRANE (LOCAL FABRICATION),

- MANUAL WINCH AND RAIL TONG (IMPORTED)

- LIGHTWEIGHT, PORTABLE, & ADJUSTABLE HEIGHT

- OVERALL DIMENSIONS: 2420×700×1460MM

- NO. OF RECOMMENDED OPERATORS 2 (1 SKILLED AND 1 HELPER)

Safety Features:

- STRUCTURAL INTEGRITY ROBUST MATERIALS: HIGH-STRENGTH

- MATERIALS FOR THE FRAME AND BODY TO WITHSTAND IMPACTS AND HEAVY LOADS

- STABILITY SUPPORTS: ADDITIONAL SUPPORTS OR STABILIZERS TO ENSURE THE RAIL CHANGER REMAINS STABLE DURING OPERATION

- REFLECTIVE MARKINGS: HIGH-VISIBILITY PAINT AND MARKINGS ENHANCE VISIBILITY, ESPECIALLY AT NIGHT OR IN LOW LIGHT

- USER-FRIENDLY DESIGN: ERGONOMICALLY DESIGNED THAT MINIMIZES THE RISK OF OPERATOR ERROR

- OPERATOR TRAINING: COMPREHENSIVE TRAINING FOR OPERATORS ON SAFETY PROTOCOLS AND EQUIPMENT HANDLING

– FABRICATION LEAD-TIME: 8-10 WEEKS

– CUSTOMIZED PER CLIENT’S SPECIFICATION

3. RAIL CARRYING ROLLER FOR NARROW GAUGE

RAIL CARRYING ROLLER FOR NARROW GAUGE

Key Features and Benefits:

- USED FOR MOVING AND CARRYING LONG NARROW

- GAUGE RAILS, CAPACITY 750 KG

- ROBUST DESIGN

- HEAVY-DUTY BALL BEARING

- OVERALL DIMENSION:60MM DIA X 180 X 160

Safety Features:

- ROBUST CONSTRUCTION: MADE FROM DURABLE MATERIALS TO WITHSTAND HEAVY LOADS AND REDUCE THE RISK OF FAILURE.

- LOAD CAPACITY INDICATORS: CLEAR MARKINGS THAT INDICATE THE MAXIMUM LOAD THE ROLLER CAN SAFELY HANDLE

- USER-FRIENDLY DESIGN: ERGONOMICALLY DESIGNED THAT MINIMIZES THE RISK OF OPERATOR ERROR

- OPERATOR TRAINING: COMPREHENSIVE TRAINING FOR OPERATORS ON SAFETY PROTOCOLS AND EQUIPMENT HANDLING

– FABRICATION LEAD-TIME: 3-4 WEEKS

– CUSTOMIZED PER CLIENT’S SPECIFICATION

4. CLIP PULLER/PAN PULLER

CLIP PULLER / PAN PULLER

Key Features and Benefits:

- HEAVY-DUTY HARDENED STEEL, SUITABLE FOR REMOVING 37KG RAIL FASTENING SYSTEM

- OVERALL DIMENSION: 1000MM LONG

– FABRICATION LEAD-TIME: 3-4 WEEKS

-CUSTOMIZED PER CLIENT’S SPECIFICATION

5. PORTABLE RAIL CUTTER

PORTABLE RAIL CUTTER

Key Features and Benefits:

Specificiations:

- EASY TO USE, DERAIL-PROOF, QUICK & PRECISE CUTTING

- GASOLINE ENGINE MODEL: HONDA GX200 (FOUR-STROKE)

- GASOLINE ENGINE POWER: 3.7KW

- GASOLINE ENGINE SPEED: 3600R/MIN

- MAXIMUM SPINDLE SPEED: >3400R/MIN

- THIN DISK GRINDING WHEEL SPECIFICATIONS: 400X4X32MM

- MAX. WORKING LINE SPEED OF THE GRINDING WHEEL: >80M/S

- CUTTING TIME: 60KG/M RAIL <120S

- USAGE TIMES OF CUTTING DISK: 50 KG/M >4 TIMES, 60KG/M USED > 3 TIMES

- WEIGHT (EXCLUDING FUEL): 42 KG

- DIMENSION: 910X520X830MM

- AVAILABILITY: 8-10 WEEKS, CHINA

6. MECHANICAL RAIL TRACK JACK

Key Features and Benefits:

- RATED TOP LIFTING RORCE: 150KN

- RATED HOOK LIFTING FORCE: 78KN

- INITIAL HEIGHT: 50MM

- LEVER LENGTH: 1.5M

- DIMENSIONS: 420X565X522

- WEIGHT: <25 KG

- AVAILABILITY: 8-10 WEEKS, CHINA

7. MANUAL RAIL THONG

MANUAL RAIL THONG

Key Features and Benefits:

- UP TO 60KG/M RAILS

- USED TO SAFELY MOVE RAIL

- OVERALL DIMENSIONS: 620MM X 350MM

- AVAILABILITY: 8-10 WEEKS, CHINA

8. OTHERS

We also accommodate customized fabrication of other rail track equipment based on each client’s unique specifications.

Our Services

-

RAIL TRACK EQUIPMENT FABRICATION